News Story

Intensive 4-Day Electronics Failure Analysis Course at CALCE a Success

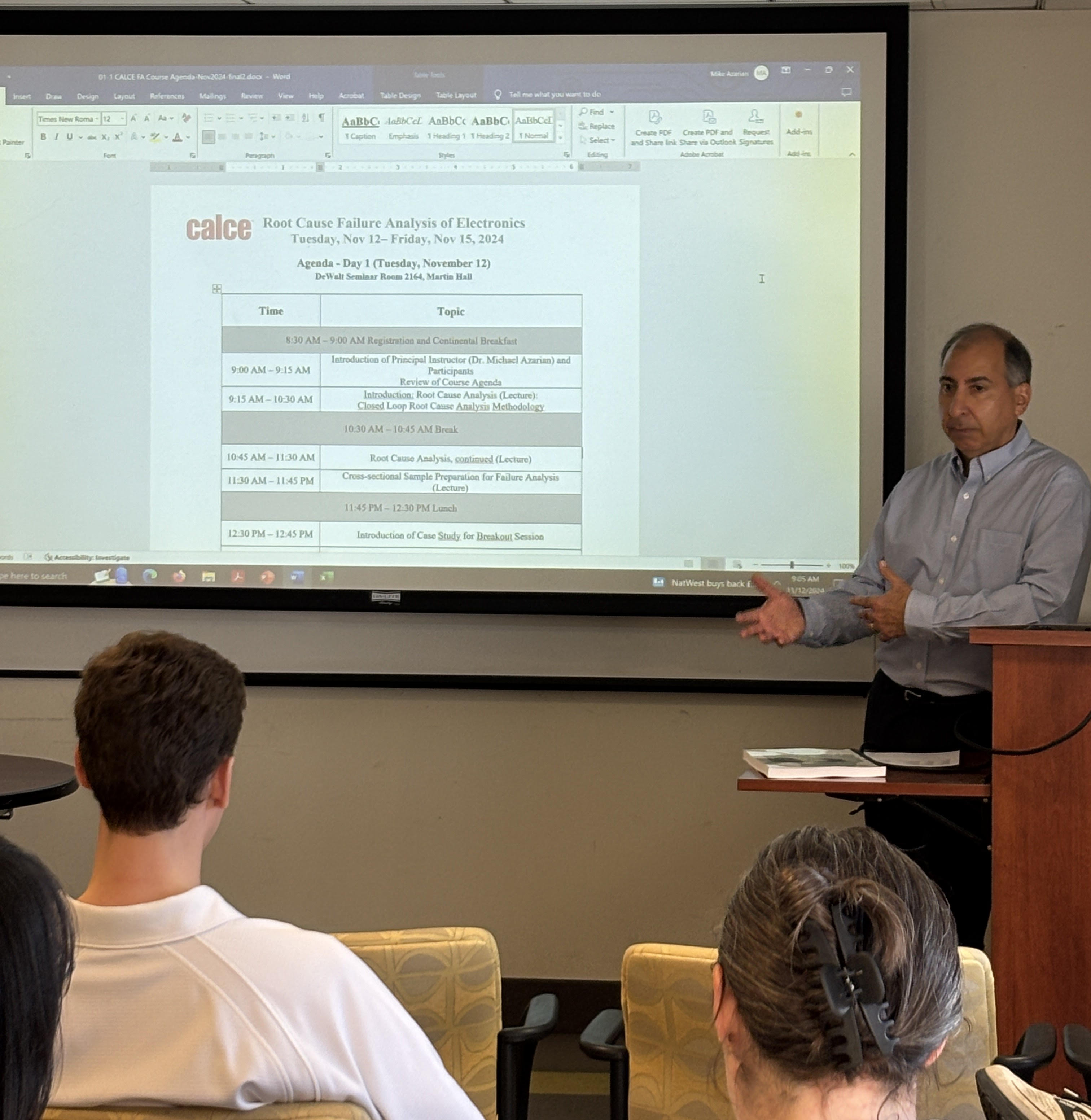

College Park, MD – On November 12-15, 2024, CALCE hosted its highly anticipated annual four-day short course on failure analysis of electronics. This limited enrollment course attracted professionals from prominent organizations in the aerospace, defense, and technology sectors from the U.S. and Europe. From November 12 to 15, 2024, the course provided participants with interactive classroom lectures and hands-on training in understanding and resolving failures in electronic products.

Dr. Michael Azarian led the course with support from Dr. Michael Osterman and Dr. Robert Utter. CALCE graduate students Zhou He, Sahithi Maddipatla, Soma Roy, Nikhil Kulkarni, Devon Richman, Clifton Buxbaum, Rutvik Davuluri, and Aniket Bharamgonda led laboratory demonstrations of various test methods and characterization equipment.

Through a blend of classroom lectures, case study group sessions, live demonstrations, and practical laboratory training, attendees gained valuable insights into the latest failure analysis methods. The lectures covered root cause analysis methodology, physics of failure-based reliability analysis, failure mechanisms in electronics, and materials analysis techniques. With a history of having been presented to hundreds of attendees over more than fifteen years, this course stands out as the pre-eminent comprehensive short course on failure analysis of electronics for working professionals.

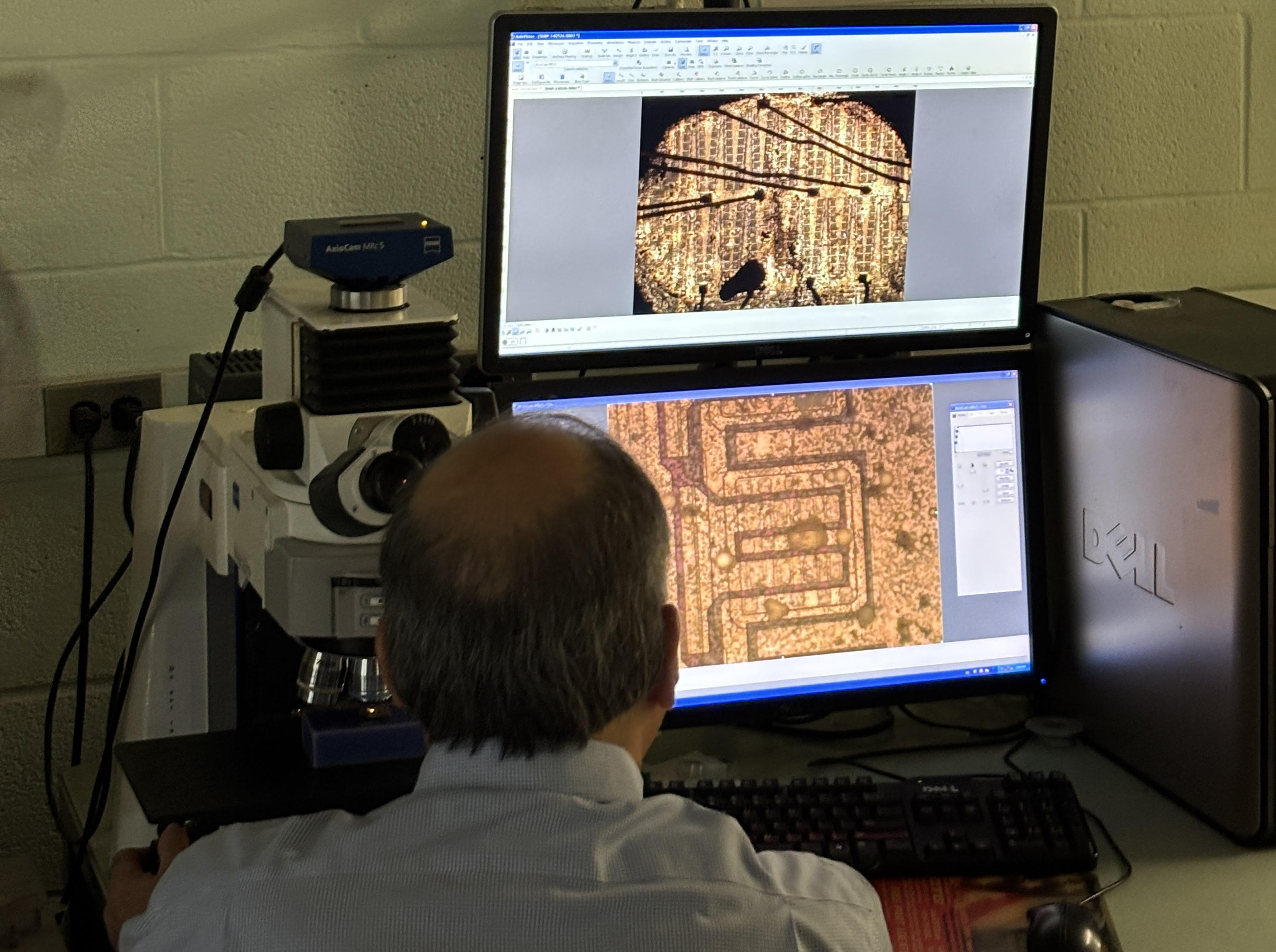

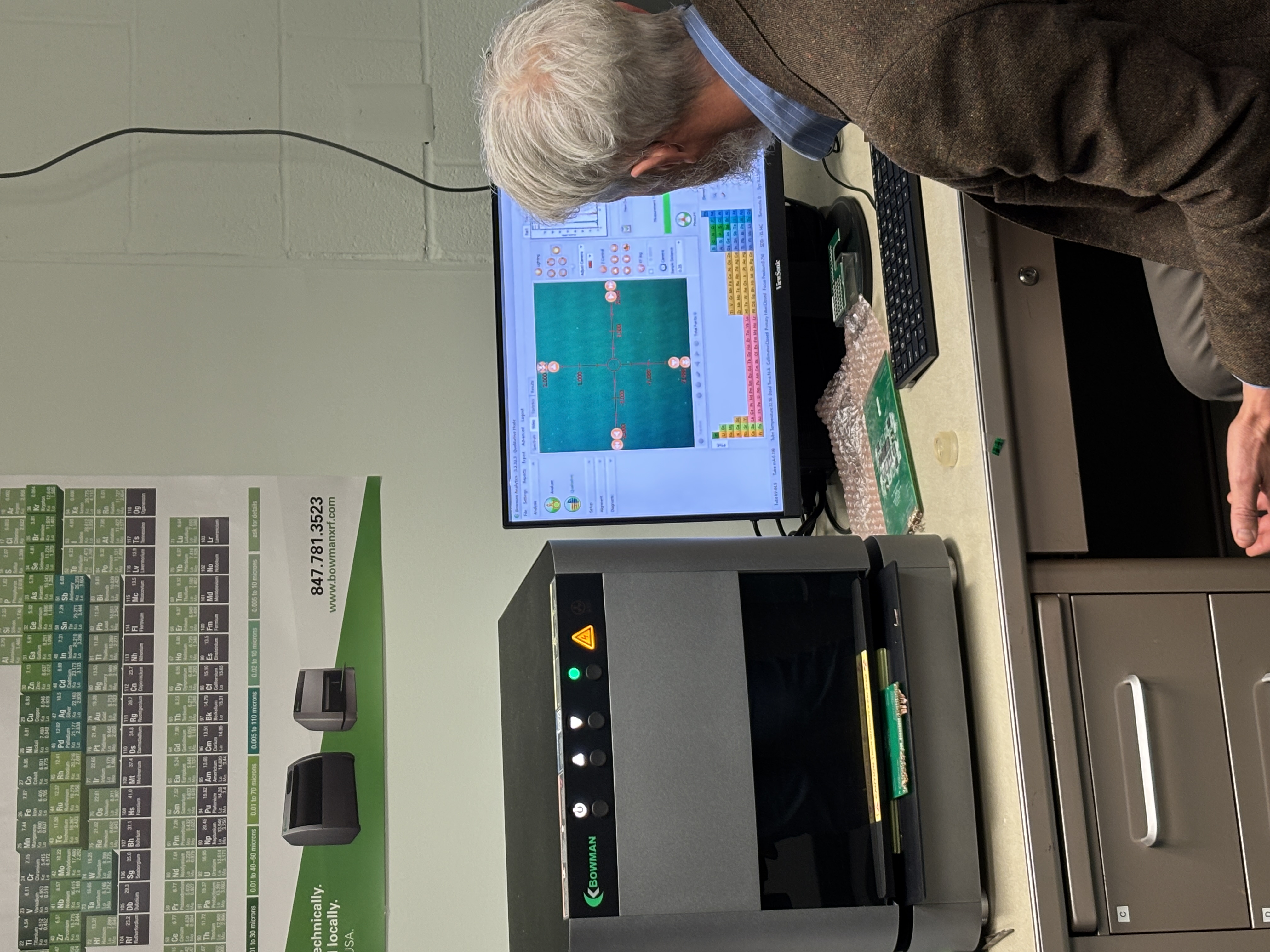

Participants were introduced to the Closed Loop Root Cause Analysis methodology, which helped them understand the structured process of identifying and resolving failure causes through systematic investigation. Some of the non-destructive techniques covered were Optical Microscopy, SEM Imaging, X-ray Imaging, and Acoustic Microscopy. Participants were introduced to Scanning Electron Microscopy (SEM) and associated elemental analysis techniques to analyze failures at the microscopic level. Participants engaged in hands-on training with cross-sectional sample preparation. Laboratory demonstrations were given on techniques such as X-ray Fluorescence Spectroscopy, Thermo-mechanical Analysis (TMA), Nanoindentation, FTIR (Fourier Transform Infrared Spectroscopy), and advanced tools like Focused Ion Beam (FIB) Etching, Transmission Electron Microscopy (TEM), and even Quantum Diamond Microscopy.

|

|

|

|

Participants came from organizations such as the U.S. Air Force, Danfoss, Lockheed Martin, Lenovo, and Blue Origin. These industry leaders brought diverse perspectives to the course, further enriching the learning experience for all involved.

Comments from the attendees on the course included:

“This short course covered most of the knowledge and techniques needed for failure analysis, as well as the instruments used for lab analysis.”

“It is very informative, with tons of examples, photos, and data that were really impressive. Excellent course!”

“The material was delivered in a clear and concise manner. The content was comprehensive.”

“Great course. Well organized.”

Comments on the introductory lecture on root cause failure analysis included:

“This lecture is a great resource for systematically understanding what failure analysis is.”

Comments on the case study breakout sessions included:

“Open discussion in a group setting was engaging.”

“Materials are very well organized, and it is a good case study to establish an FA workflow and how to use the 5-Whys FA method to teach the root cause step by step.”

As the demand for high-reliability electronics continues to grow in critical industries, the knowledge gained from these sessions will prove vital for professionals striving to enhance the performance and longevity of electronic products.

For more information on professional development courses offered by CALCE, visit https://calce.umd.edu/professional-development-courses and contact us at education@calce.umd.edu.

Published November 25, 2024