News Story

New, Innovative UMD Course Teaches In-Demand Skills

Grad Assistant Weijian Xian teaches the lab portion of the Advanced Manufacturing Lab

A new approach to teaching advanced fabrication skills is leading the way in preparing a semiconductor manufacturing workforce for the future. The University of Maryland (UMD) now offers ENEE 419M, “Advanced Manufacturing Lab” (AML), an innovative, multidisciplinary class for undergraduates and select graduate students. A new teaching method being pioneered in this course eventually will allow universities to teach in-demand skills and provide broad access to state-of-the-art technology throughout the country. This course is now being taught at the College Park campus and will be offered at the University System of Maryland at Southern Maryland UMD MATRIX Lab in Fall 2025.

“The Advanced Manufacturing Lab teaches students a variety of highly sought-after microelectronics fabrication skills useful in graduate research and technical workplaces,” said University of Maryland Herbert Rabin Distinguished Chair in Engineering Dr. Reza Ghodssi, one of the course’s creators. “The course provides state-of-the-art opportunities and access to cutting-edge technologies, independent of clean room environments.”

The AML is a joint effort between Dr. Ghodssi and Assistant Professor Dr. Kevin Daniels (ECE); they created the course with input from their students and alumni. It is relevant to and supported by multiple UMD units: A. James Clark School of Engineering, Electrical & Computer Engineering, Materials Science & Engineering, Bioengineering, and the Fischell Institute for Biomedical Devices.

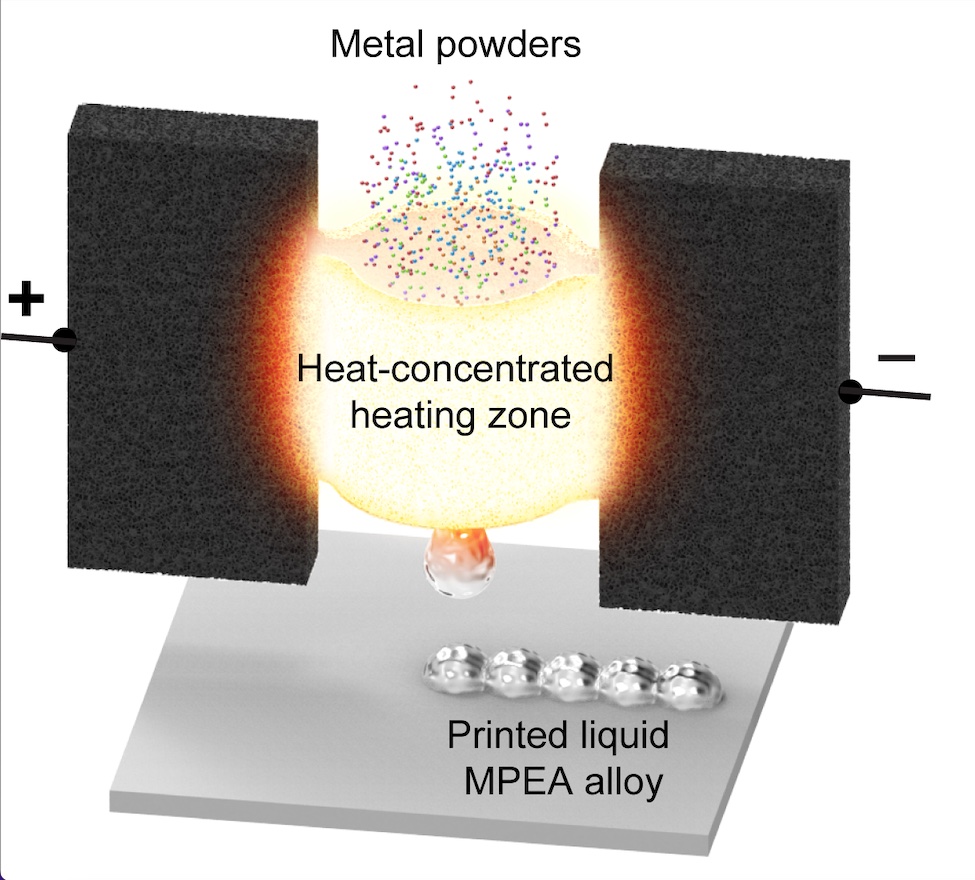

The course includes four modules: benchtop soft materials lithography, hybrid manufacturing, nanomaterial – nanoparticles, and system integration/case study. Fabrication topics and skills can be updated as technology advances. In addition, individual modules can be taught as stand-alone short courses—helpful to attract more types of students including area high school STEM teachers and industry partner employees. AML students will gain knowledge and experience typically only acquired in on-the-job training.

“This modular, interdisciplinary teaching method is an innovative way to approach education,” Dr. Daniels said. “Students will learn the latest and greatest skills and be able to apply them in many engineering fields.”

Recently, both the federal government and industry have invested in increasing chip production in the U.S. through the CHIPS and Science Act of 2022 and the U.S. Innovation and Competition Act of 2021. There are many economic, security, and technological reasons for producing chips domestically. As an article from The Economist points out, the country needs a skilled workforce to run the new chip facilities. Chips are used in consumer products, automobiles, computers, micro medical devices and more.

The AML’s portability allows the course to be taught across University System of Maryland campuses. Future sites could include the University of Maryland School of Medicine in Baltimore, the University of Maryland Eastern Shore, and the Universities at Shady Grove. The course contributes to UMD’s “Grand Challenges” mission. It is a real-life engineering research investment that addresses complex issues facing the state, nation, and world.

To learn more about microelectronics workforce development, read our story about DREEM, a National Science Foundation (NSF) grant funded by NSF’s Experiential Learning for Emerging and Novel Technologies (ExLENT) program.

Published October 4, 2023